On a recent trip to Tel Aviv I had the opportunity to visit two companies, Aleph Farms & SuperMeat, who are at the forefront of the food tech boom underway in Israel (rivalled only by Silicon Valley).

The premise is this: it takes over 2 years, tens of thousands of gallons of water, and 20,000 lbs of feed to grow a cow to slaughter-size. Once slaughtered, only 30% is edible, and the rest of the cow gets recycled into other industries: leather, glue, makeup, sausage. Why spend so many resources, invest so much time, and create such negative effects on the environment…to get beef? Why not simply grow the part of the cow you wish to eat?

Amazingly, that technology now exists. A few years ago, a lab at Technion University in Israel developed the technology to grow human tissue in a lab for use in transplants, skin grafts, that kind of thing. Food tech entrepreneurs wondered if they could use the same technology to create food to eat – and they succeeded.

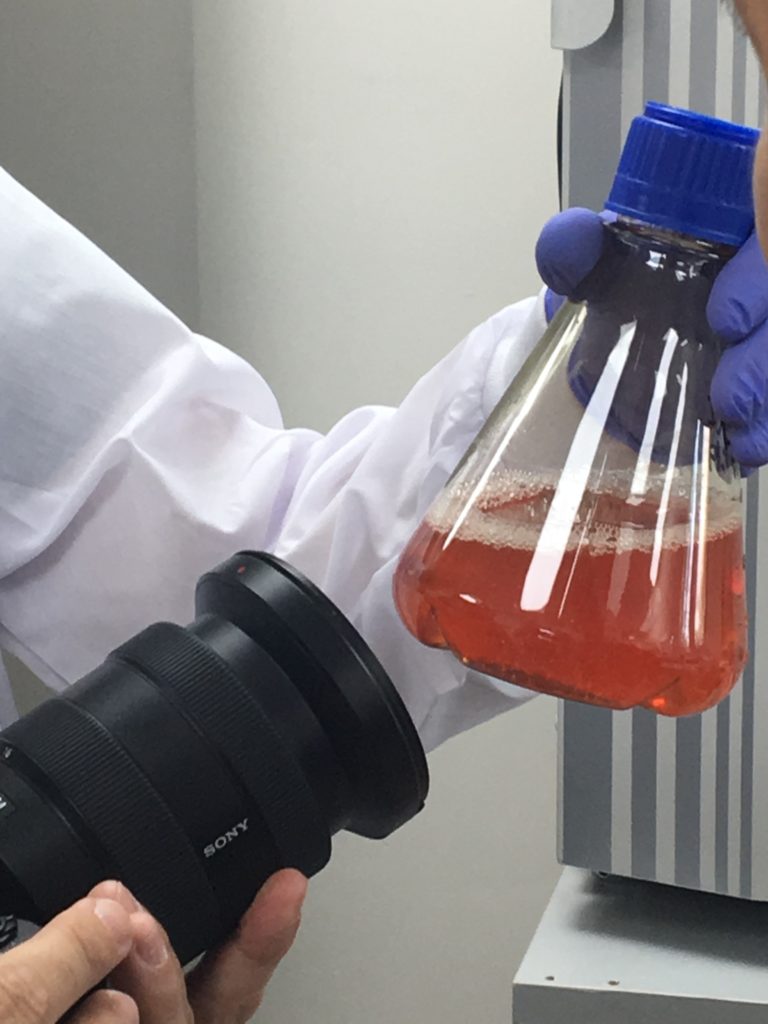

Both companies work the same way. They take a small tissue biopsy from a living cow (Aleph Farms) or chicken (SuperMeat), leaving the animal to continue chewing cud or clucking about the henhouse. From that tissue sample they extract stem cells, grow them, multiply them, and when they have a sizeable supply, they direct the stem cells to become muscle, blood or fat cells. (Stem cells, like the wild card in Uno! are able to become whatever you need them to be.)

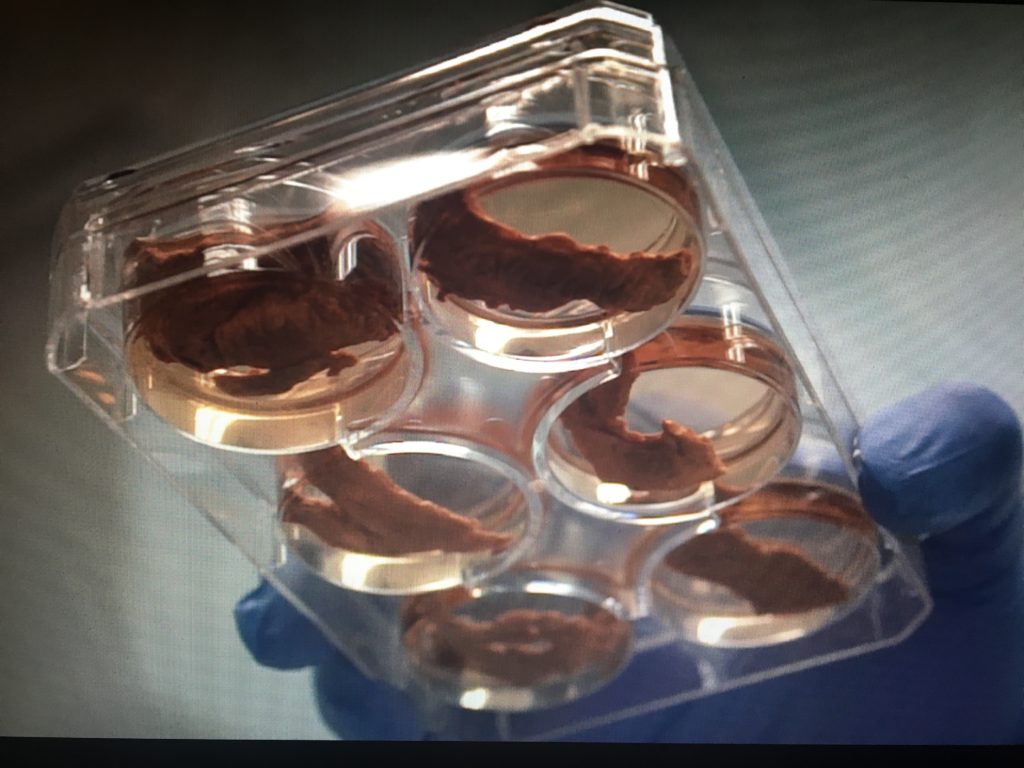

Scientists then stitch together the correct combination of muscle/blood/fat cells to create a small piece of tissue, which then has a steady diet of amino acids, minerals and glucose in a petri dish until it is sizeable enough to eat.

At Aleph Farms, I tried a piece of their steak… it’s small, and it’s thin, like a shaving of beef you’d have in a Philly Cheesesteak. It took only 2 weeks to grow. And when sauteed briefly in a hot pan with some soy sauce and sesame oil… it was… delicious. If you had put that in my mouth without telling me what it was, I’d simply answer STEAK. The texture was fibrous and chewy; the exterior was carmelized, and the taste was identical.

At SuperMeat they’re doing the same, with chicken. Developing ground chicken for nuggets was easy – but they’ve also just now mastered a small chicken filet… moist, chewy, chicken-y. As they point out, you only need one tissue sample to create an infinite amount of stem cells, which multiply exponentially. You only need one living animal to create a nearly infinite supply of lab meat.

I went into the labs skeptical.. but after tasting the meat, and seeing the process, I’m a convert. Beyond even the animal-rights or environmental concerns… by creating meat in this process, they avoid the need for hormones or antibiotics. Meat created in a clean biolab doesn’t need to ward against e coli or any of the many diseases found on a farm.

I know for many it’s a leap to consider eating lab meat. It’s also a leap for many to consider eating many of the things I’ve eaten for this blog. But it’s tasty, healthier, and a solution to the many problems plaguing the planet right now. (And hey, if you eat an Entenman’s donut or a Lean Cuisine, you’re already eating lab food.) When this hits the restaurant near you in 5 years and the shelves 2 years after that… give it a try. I think you’ll be as pleasantly surprised as I am.

No comments yet.